ʻO nā ʻāpana kaʻa paʻa sila

wehewehe

| ʻAno Huahana | huahana hoʻopilikino | |||||||||||

| Hana Hookahi | ʻO ka hoʻomohala ʻana a me ka hoʻolālā-hoʻouna ʻana i nā laʻana-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Kaʻina hana | hehi, kulou, kiʻi hohonu, hana ʻia me ka pepa, wili, ʻoki laser etc. | |||||||||||

| Nā mea waiwai | kalapona kila, stainless steel, aluminika, keleawe, galvanized kila etc. | |||||||||||

| Anana | e like me nā kaha kiʻi a ka mea kūʻai aku. | |||||||||||

| Hoʻopau | E kāpīpī i ka pena, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Wahi noi | ʻO nā ʻāpana kaʻa, nā ʻāpana mīkini mahiʻai, nā ʻāpana mīkini ʻenekinia, nā ʻāpana ʻenekinia kūkulu, nā lako kīhāpai, nā ʻāpana mīkini pili i ke kaiapuni, nā ʻāpana moku, nā ʻāpana mokulele, nā paipu paipu, nā ʻāpana hāmeʻa, nā ʻāpana pāʻani, nā ʻāpana uila, etc. | |||||||||||

Pono

1. Ma mua o 10 makahikio ka ike kalepa ma na aina e.

2. Hoolakolawelawe hoʻokahimai ka hoʻolālā mold a hiki i ka lawe ʻana i nā huahana.

3. ʻO ka manawa hāʻawi wikiwiki, e pili ana30-40 mau lā.Loaʻa i loko o hoʻokahi pule.

4. ʻO ka hoʻokele maikaʻi a me ke kaʻina hana (ISOmea hana i hōʻoia ʻia a me ka hale hana).

5. ʻOi aku nā kumukūʻai kūpono.

6. ʻOihana, loaʻa i kā mākou hale hanaʻoi aku ma mua o 10makahiki o ka mōʻaukala ma ke kahua o ka metala stamping sheet metala.

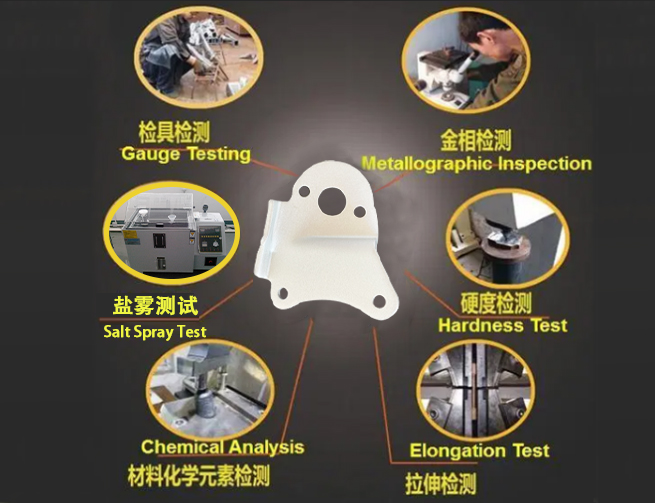

Hoʻoponopono maikaʻi

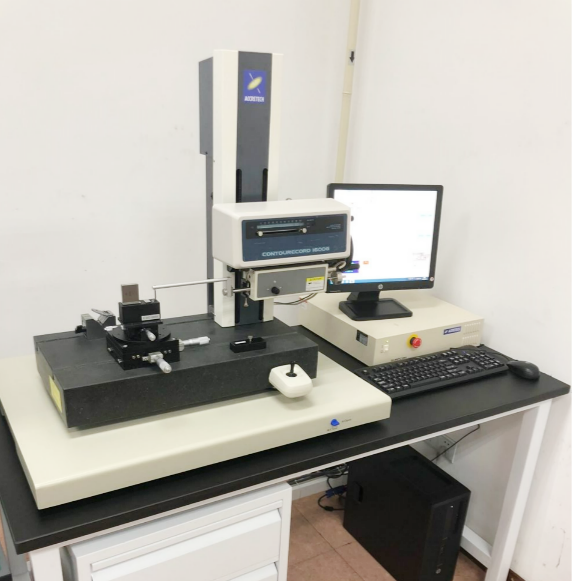

Vickers mea paʻakikī.

Mea hoʻohana ʻikena.

Mea kani spectrograph.

ʻEkolu mea kani hoʻohui.

Kii Hoouna

Kaʻina Hana Hana

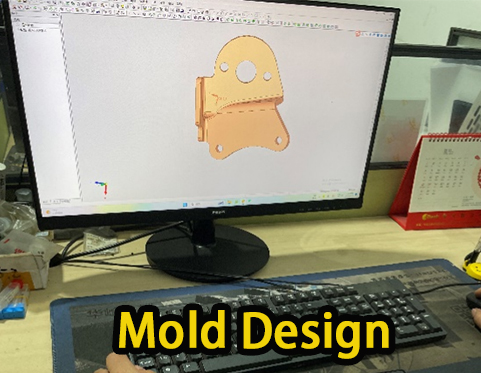

01. Mold design

02. Hoʻoheheʻe ʻia

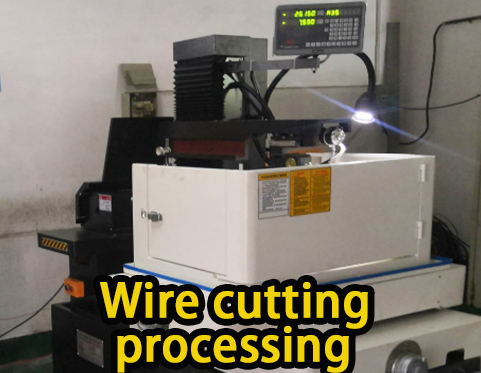

03. ʻO ka hana ʻoki uea

04. Mold wela lapaʻau

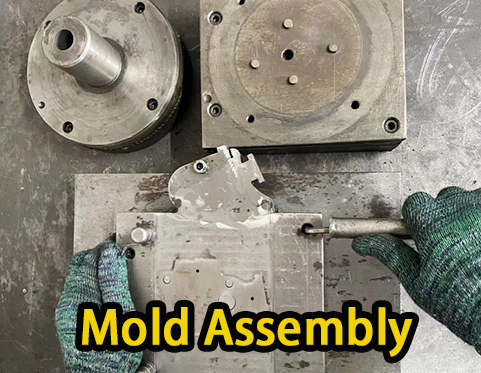

05. Hui poni

06. Mold debugging

07. Ka hoopau ana

08. electroplating

09. Ho'āʻo Huahana

10. Pūʻolo

Nā ʻano heʻi

Hāʻawi mākou i hoʻokahi a me ka multistage, holomua holomua, hohonu huki, ʻehā slide, a me nā ʻano hana stamping ʻē aʻe e hōʻoia i ke ala kūpono loa no ka hana ʻana i kāu huahana.Hiki i nā poʻe akamai o Xinzhe ke hoʻohālikelike i kāu pāhana me ka hōʻailona kūpono ma ka nānā ʻana i kāu kumu hoʻohālike 3D i hoʻoili ʻia a me nā kiʻi ʻenehana.

- Hoʻohana ʻo Progressive Die Stamping i nā make a me nā ʻanuʻu e hana i nā ʻāpana hohonu ma mua o ka mea maʻamau e hiki ke loaʻa ma o ka make hoʻokahi.Hāʻawi ia i nā geometries he nui i kēlā me kēia ʻāpana i ko lākou hele ʻana i nā make like ʻole.Ua kūpono kēia ʻenehana i ka leo kiʻekiʻe a me nā ʻāpana nui e like me nā mea i loko o ka ʻoihana kaʻa.He kaʻina like ka hoʻololi ʻana i ka die stamping, koe wale nō ka hana ʻana i kahi mea hana i hoʻopili ʻia i kahi kaula hao i huki ʻia ma ke kaʻina holoʻokoʻa.Wehe ʻia ka mea hana a hoʻoneʻe ʻia ma kahi conveyor.

- Hoʻokumu ʻo Deep Draw Stamping i nā stampings me nā lua hohonu, e like me nā rectangles i hoʻopaʻa ʻia.Hoʻokumu kēia kaʻina hana i nā ʻāpana paʻa mai ka hoʻololi ʻana o ka metala i hoʻopaʻa i kona ʻano i loko o kahi ʻano crystalline.Hoʻohana pinepine ʻia ka stamping kiʻi maʻamau, e pili ana i nā make pāpaʻu i hoʻohana ʻia e hana i ke metala.

- Hoʻohālikelike ʻo Fourslide Stamping i nā ʻāpana mai nā koʻi ʻehā ma kahi o ka ʻaoʻao hoʻokahi.Hoʻohana ʻia kēia ʻano hana no ka hana ʻana i nā ʻāpana liʻiliʻi liʻiliʻi me nā ʻāpana uila e like me nā mea hoʻohui kelepona kelepona.ʻO ka hāʻawi ʻana i ka maʻalahi o ka hoʻolālā ʻana, nā kumukūʻai haʻahaʻa haʻahaʻa, a me nā manawa hana wikiwiki, kaulana ʻo fourslide stamping i nā ʻoihana aerospace, lāʻau lapaʻau, automotive, a me nā ʻoihana uila.

- ʻO ka Hydroforming kahi hoʻololi o ka stamping.Hoʻokomo ʻia nā lau ma luna o kahi make me ke ʻano o lalo, ʻoiai ʻo ke ʻano o luna he ʻōpū o ka ʻaila e hoʻopiha i ke kaomi kiʻekiʻe, e kaomi ana i ka metala i ke ʻano o ka make haʻahaʻa.Hiki ke hydroformed nā ʻāpana he nui i ka manawa like.ʻO ka Hydroforming kahi hana wikiwiki a pololei, ʻoiai pono ia i kahi ʻoki make e ʻoki i nā ʻāpana mai ka lau ma hope.

- ʻOkiʻoki ʻia nā ʻāpana mai ka pepa ma ke ʻano he hana mua ma mua o ka hana ʻana.ʻO Fineblanking, kahi hoʻololi o ka blanking, hana i nā ʻoki kikoʻī me nā ʻaoʻao maʻemaʻe a me ka ʻili palahalaha.

- ʻO Coining kekahi ʻano blanking e hana ana i nā mea hana liʻiliʻi poepoe.No ka mea he ikaika nui ka hana ʻana i kahi ʻāpana liʻiliʻi, hoʻopaʻakikī ʻo ia i ka metala a hoʻoneʻe i nā burrs a me nā ʻaoʻao ʻōpala.

- ʻO ke kuʻi ke kūʻē i ka blanking;pili ia i ka wehe ʻana i nā mea mai ka mea hana ma mua o ka wehe ʻana i nā mea e hana ai i kahi mea hana.

- Hoʻokumu ʻo Embossing i kahi hoʻolālā ʻekolu-dimensional i loko o ka metala, i hoʻokiʻekiʻe ʻia ma luna o ka ʻili a i ʻole ma ke ʻano o nā puʻupuʻu.

Hana ʻia ka piko ma kahi axis hoʻokahi a hoʻohana pinepine ʻia no ka hana ʻana i nā kiʻi ma nā ʻano U, V, a i ʻole L.Hoʻokō ʻia kēia ʻano hana ma ka hoʻopaʻa ʻana i kekahi ʻaoʻao a kulou i kekahi ma luna o ka make a i ʻole ke kaomi ʻana i ke metala i loko a i ʻole i ka make.Ke kulou nei ka Flanging no nā ʻāpana a i ʻole nā ʻāpana o kahi mea hana ma mua o ka ʻāpana holoʻokoʻa.

FAQ

Q1: He aha kā mākou e hana ai inā ʻaʻohe kiʻi kiʻi?

A1: E ʻoluʻolu e hoʻouna i kāu hōʻailona i kā mākou hale hana, a laila hiki iā mākou ke kope a hāʻawi iā ʻoe i nā hopena maikaʻi aʻe.E ʻoluʻolu e hoʻouna mai iā mākou i nā kiʻi a i ʻole nā kikoʻī me nā ana (Mānoanoa, lōʻihi, kiʻekiʻe, ākea), CAD a i ʻole 3D file e hana ʻia no ʻoe inā kau ʻia ke kauoha.

Q2: He aha ka mea e ʻokoʻa ai ʻoe mai nā poʻe ʻē aʻe?

A2: 1) ʻO kā mākou lawelawe maikaʻi loa E hoʻouna mākou i ka ʻōlelo i nā hola 48 inā loaʻa ka ʻike kikoʻī i nā lā hana.2) ʻO kā mākou manawa hana wikiwiki No nā kauoha maʻamau, e hoʻohiki mākou e hana i loko o 3 a 4 mau pule.Ma ke ʻano he hale hana, hiki iā mākou ke hōʻoia i ka manawa hāʻawi e like me ka ʻaelike maʻamau.

Q3: Hiki paha ke ʻike i ke ʻano o kaʻu mau huahana me ka ʻole e kipa aku i kāu hui?

A3: E hāʻawi mākou i kahi papa hana kikoʻī a hoʻouna i nā hōʻike pule me nā kiʻi a i ʻole nā wikiō e hōʻike ana i ka holomua machining.

Q4: Hiki iaʻu ke loaʻa i kahi kauoha hoʻokolokolo a i ʻole nā mea hoʻohālike wale nō no nā ʻāpana he nui?

A4: E like me ka huahana i hoʻopilikino ʻia a pono e hana ʻia, e hoʻopiʻi mākou i ke kumukūʻai hāpana, akā inā ʻaʻole ʻoi aku ke kumukūʻai o ka hāpana, e hoʻihoʻi mākou i ke kumu hoʻohālike ma hope o kou kau ʻana i nā kauoha lehulehu.